>> see end of page to read about latest prototype

My first test was a very basic one.

Since I don’t know how to model in 3D, I checked for existing hair clips stl-files online. The most appealing one was the 3D printed hair clip on thingiverse.

I downloaded the file and ordered a print ( in ABS) at 3dee in Antwerp. Wow, it was a bit rough and stiff, but it really worked… for a while.

I downloaded the file and ordered a print ( in ABS) at 3dee in Antwerp. Wow, it was a bit rough and stiff, but it really worked… for a while.

Now it’s broken.

Good things:

- The simplicity of the one piece design.

- Any colour is possible

- Good possibilities for customization, (see the version with four stars on the outer bar).

To improve:

- Firmness

- Flexibility of the clasp

Update September 1 – 2016

I should also check some other interesting clips on thingiverse: the Mini Hair Claw and the banana hairclip.

Update September 21 – 2016

I ordered the X-shaped Lane’s hairclip on Shapeways in blue plastic. It’s printed and finished really beautiful and after assembling the two parts you can actually open and close it. But the hair clip is a bit smaller than I expected, and due to the pointy spikes on the inside it is not easy to slide the hair clip to the top of a lock of hair.

I ordered the X-shaped Lane’s hairclip on Shapeways in blue plastic. It’s printed and finished really beautiful and after assembling the two parts you can actually open and close it. But the hair clip is a bit smaller than I expected, and due to the pointy spikes on the inside it is not easy to slide the hair clip to the top of a lock of hair.

Update October 05 – 2016

My lucky day! I found the plastic B&D model I was looking for (Grazie Mille Isabelle!). It is not an authentic one, but for prototyping it will do. This friday we will make a 3D scan and test some customization options. The hair clip on the picture is not 3D printed yet, its the original. Looking forward to next steps.

My lucky day! I found the plastic B&D model I was looking for (Grazie Mille Isabelle!). It is not an authentic one, but for prototyping it will do. This friday we will make a 3D scan and test some customization options. The hair clip on the picture is not 3D printed yet, its the original. Looking forward to next steps.

Update October 13 – 2016

Last Friday I went to 3dee in Antwerp to scan and print the little red hair clip. Unfortunately, they couldn’t help me that fast :/

I learned and understood it takes some time to develop a digital 3D file. The person in the shop however was very helpful and explained me the options

- scan the object without any additional engeneering – cost approx 290€ – result: might cause some difficulties to scan and print afterwards especially because of the tiny pins

- scan the object with additional engineering – cost approx 450€ – result: perfect copy of the red hairlip original

- no scan – start from scratch and draw the piece as identical as possible – cost approx 150€ – result: not a perfect copy of the original – but maybe hard to see the difference at first sight

I decided to test first with the latest option, which was the most interesting in terms of budget in proportion to quality.

I decided to test first with the latest option, which was the most interesting in terms of budget in proportion to quality.

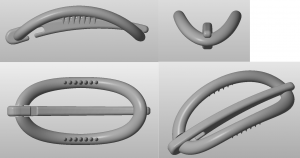

Today I got the first sketch. Wow – it looks already very real. And now we take the next step: print it.

Again patience is required – it will take them a few days to deliver the first test prints : one white copy – original size and a second copy increased size (7,5 cm).

Update October 13 – 2016

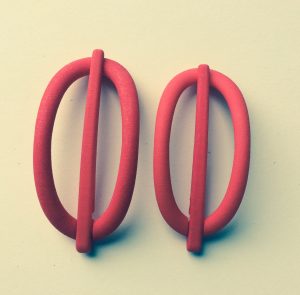

The first prototype is ready! It’s still very basic, but it really works.

The first prototype is ready! It’s still very basic, but it really works.

It’s printed in polyamide and thus the surface is fine and white. It looks like it is made from sugar, slightly porous. But actually it is a strong and somewhat flexible material, that allows some pressure when attaching the clip into your hair.

Unfortunately it hasn’t the beautiful shiny colours as created by Ketty Dalsgaard for Buch and Deichmann. I will definitely explore further on the choice of material.

Also I’m thinking about some themes to personalize the hair clip. Maybe this could be done with very simple objects such as letters or shapes. At the time Buch and Deichmann designed a few sets with beautiful little flowers. But it could be equally fun, to come up with a limited edition. In that case the surreal birds from dutch artist Piet Parra are high on my whishlist.

Update December 11 – 2016

Although the experts at 3dee had discouraged it, I was curious to find out how the hair clip would look in PLA. It was interesting to see how the print was built upon the support structure, but unfortunately after removing it the pin was a bit damaged.

- The color is bright and the material feels really light weight.

To improve:

- Quality of the print on the lower arc

- Use finer sandpaper to remove the support structure

I am also testing a new polyamide print with a customised quote on the outer bow. Next week it will be ready. Keep U posted.

Update Februari 05 – 2017

End of Januari I started a course ‘Additive Manufacturing‘ at the University of Ghent to learn more about manufacturing with different materials. I hope the classes will bring new insights, as I experienced some difficulties with the current testing materials.

With the existing STL file of the “B&D-like” hairclip model I have been testing two different materials/additive manufacturing processes via Shapeways:

- PLA (Material extrusion – nozzle)

- Strong & Flexible Polished (SLS – use a bed of Nylon powder and sinter the powder with a laser layer by layer)

To process the Shapeways order, regardless the material, I had to upload two different STL files, one for the bow and one for the stick. This makes the order as a whole more expensive, but when uploading the STL as a whole (as I did first), both parts clung to each other tight and thus the hairclip was not usable. Fortunately Shapeways was willing to do a refund for this – much appreciated. Note: Ordering the hairclip on i-materialise was not possible because the stick-file was rejected (because the dimensions were too small).

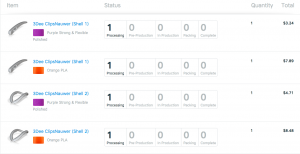

The order consisted of 4 items:

- 1 x 3Dee ClipsNauwer (Shell 1) in Purple Strong & Flexible Polished

- 1 x 3Dee ClipsNauwer (Shell 2) in Purple Strong & Flexible Polished

- 1 x 3Dee ClipsNauwer (Shell 1) in Orange PLA

- 1 x 3Dee ClipsNauwer (Shell 2) in Orange PLA

Was I happy with the result?

The purple hairclip gives the best result. The color is pretty evenly colored and both form and details are sharp.

The purple hairclip gives the best result. The color is pretty evenly colored and both form and details are sharp.

Downsides:

- It’s a pity though the material does not look at all like the beautiful shiny plastic of the original pins.

- The colours one can order are limited. I found out via 3Deee that choosing your own colour for PA requires an additional start-up cost of 50 euros per color. Which is not a big deal if you make a big order, but for ultimate personalization (one colour per person) it might be a show-stopper on price.

The orange hairclip in PLA (which was twice as expensive in price) had the same issues as the red version above. It is obvious that the selected 3D-printing technology combined with the applied printing direction makes that the top of the arc is very rough and uneven. It’s not a nice shiny accessory.

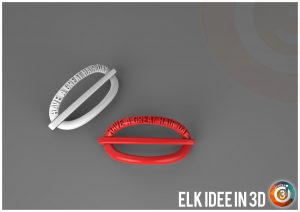

As promised in a former post, pleas e see hereby the first test with a texted hair-clip bow (credits to Michaël from 3dee.be), which shows the potential for further variations. This is what I want to continue testing with: besides texts, personalisation can also be done with shapes, or a combination of both. Why not a romantic one for Valentine’s Day?

e see hereby the first test with a texted hair-clip bow (credits to Michaël from 3dee.be), which shows the potential for further variations. This is what I want to continue testing with: besides texts, personalisation can also be done with shapes, or a combination of both. Why not a romantic one for Valentine’s Day?

To be continued.

Update May 05 – 2017

Some time has passed, but I have made progress with the prototypes.

The following assays were carried out:

- Test with different sizes

- Test with different materials/3D printing solutions

- Test more colours

- Test with personalised messages

- And about this I’m really enthusiastic: Test with a PolyJet (Thanks to Seido Solutions)

Test with different sizes

With the exact s ame STL file I can order the barrettes at Shapeways in different sizes. As a result the hair pin is scaled, and thus easily adaptable for thicker/thinner hair or for children/adults.

ame STL file I can order the barrettes at Shapeways in different sizes. As a result the hair pin is scaled, and thus easily adaptable for thicker/thinner hair or for children/adults.

The picture shows 10% magnification. The pricing difference was minimal:

- Normal size: € 4,71 (Shell) + € 3,24 (Stick)

- +10% size: € 5,23 (Shell) + € 3,45 (Stick)

- Compared to Normal size PLA pricing: € 8,48 (Shell) + € 7,89 (Stick)

Test with different materials /3D printing solutions

As previously described I think the plastics are better suited to the original design of the pin and its intense everyday use than the polyamide (SLS). But when printed and after removal of the support structures, none of the plastic (PLA/ASA) printed pins looks beautifully finished. As you can see in the picture (the plastics are the two most right ones), there are inaccuracies in the printout at various places.

As previously described I think the plastics are better suited to the original design of the pin and its intense everyday use than the polyamide (SLS). But when printed and after removal of the support structures, none of the plastic (PLA/ASA) printed pins looks beautifully finished. As you can see in the picture (the plastics are the two most right ones), there are inaccuracies in the printout at various places.

During on of the classes (course ‘Additive Manufacturing‘), Professor Ludwig Cardon recommended to the carry out a test with soluble support structures. I’m very grateful to Seido solutions that they helped me with this. They recommended to print in the ASA material, because of the good mechanical strength with UV resistance, combined with soluble support material. Although that hair pin (the middle in the picture) looks much better, there were are irregularities. Thus unfortunately, I think it isn’t good enough for production. Fortunately, Seido Solutions also proposed to test with PolyJet technology (see below).

Test more colours

This test is obviously the most fun to do.

This test is obviously the most fun to do.

Once you have a good design, you can customise and print your preferred colour or the colour that fits best with your outfit: once also the added value of the original Buch and Deichmann collection. Sadly, in most makerplaces, check Shapeways or iMaterialise, you don’t have an infinite choice of colors. I would prefer to print the hairpins in pastel tones, but mostly both in polyamide as in plastics you are limited to ten (rather bright) colors.

Fortunately, black is always beautiful. This is one of my favorites.

Test with personalised messages

I think the hair pin with text looks much nicer on the 3D image file (see above) than in the real printed version.

I think the hair pin with text looks much nicer on the 3D image file (see above) than in the real printed version.

However, this is what I want to continue testing with: besides texts, personalisation can also be done with shapes, or a combination of both.

Last but not least: the PolyJet test…

The idea to test with PolyJet technology was suggested by Hans Valkenaers from Seido Solutions when we were discussion the options to print with soluble support structures.

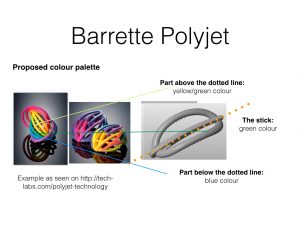

With the PolyJet technology it is possible to combine up to 6 colours. A well-applicable feature on hair accessories, that I made use of immediately by providing the following briefing for the test print:

When I found the final prints in my mailbox, I was really  blown away by their perfect finish and the subtle color gradation.

blown away by their perfect finish and the subtle color gradation.

Good things:

- Smooth and detailed print with final-product aesthetics

- Nice colors and a good gradient

- No irregularities in the material

To improve or test:

- The material could change overtime when exposed to light and heat

- The price is higher compared to polyamide (Exact price must be requested from Seido Solutions)