Update May 05 – 2017

Some time has passed, but I have made progress with the prototypes.

The following assays were carried out:

- Test with different sizes

- Test with different materials/3D printing solutions

- Test more colours

- Test with personalised messages

- And about this I’m really enthusiastic: Test with a PolyJet (Thanks to Seido Solutions)

Test with different sizes

With the exact s ame STL file I can order the barrettes at Shapeways in different sizes. As a result the hair pin is scaled, and thus easily adaptable for thicker/thinner hair or for children/adults.

ame STL file I can order the barrettes at Shapeways in different sizes. As a result the hair pin is scaled, and thus easily adaptable for thicker/thinner hair or for children/adults.

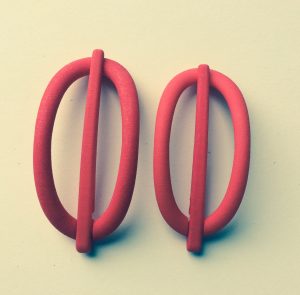

The picture shows 10% magnification. The pricing difference was minimal:

- Normal size: € 4,71 (Shell) + € 3,24 (Stick)

- +10% size: € 5,23 (Shell) + € 3,45 (Stick)

- Compared to Normal size PLA pricing: € 8,48 (Shell) + € 7,89 (Stick)

Test with different materials /3D printing solutions

As previously described I think the plastics are better suited to the original design of the pin and its intense everyday use than the polyamide (SLS). But when printed and after removal of the support structures, none of the plastic (PLA/ASA) printed pins looks beautifully finished. As you can see in the picture (the plastics are the two most right ones), there are inaccuracies in the printout at various places.

As previously described I think the plastics are better suited to the original design of the pin and its intense everyday use than the polyamide (SLS). But when printed and after removal of the support structures, none of the plastic (PLA/ASA) printed pins looks beautifully finished. As you can see in the picture (the plastics are the two most right ones), there are inaccuracies in the printout at various places.

During on of the classes (course ‘Additive Manufacturing‘), Professor Ludwig Cardon recommended to the carry out a test with soluble support structures. I’m very grateful to Seido solutions that they helped me with this. They recommended to print in the ASA material, because of the good mechanical strength with UV resistance, combined with soluble support material. Although that hair pin (the middle in the picture) looks much better, there were are irregularities. Thus unfortunately, I think it isn’t good enough for production. Fortunately, Seido Solutions also proposed to test with PolyJet technology (see below).

Test more colours

This test is obviously the most fun to do.

This test is obviously the most fun to do.

Once you have a good design, you can customise and print your preferred colour or the colour that fits best with your outfit: once also the added value of the original Buch and Deichmann collection. Sadly, in most makerplaces, check Shapeways or iMaterialise, you don’t have an infinite choice of colors. I would prefer to print the hairpins in pastel tones, but mostly both in polyamide as in plastics you are limited to ten (rather bright) colors.

Fortunately, black is always beautiful. This is one of my favorites.

Test with personalised messages

I think the hair pin with text looks much nicer on the 3D image file (see above) than in the real printed version.

I think the hair pin with text looks much nicer on the 3D image file (see above) than in the real printed version.

However, this is what I want to continue testing with: besides texts, personalisation can also be done with shapes, or a combination of both.

Last but not least: the PolyJet test…

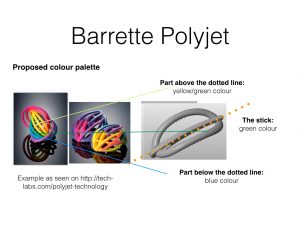

The idea to test with PolyJet technology was suggested by Hans Valkenaers from Seido Solutions when we were discussion the options to print with soluble support structures.

With the PolyJet technology it is possible to combine up to 6 colours. A well-applicable feature on hair accessories, that I made use of immediately by providing the following briefing for the test print:

When I found the final prints in my mailbox, I was really  blown away by their perfect finish and the subtle color gradation.

blown away by their perfect finish and the subtle color gradation.

Good things:

- Smooth and detailed print with final-product aesthetics

- Nice colors and a good gradient

- No irregularities in the material

To improve or test:

- The material could change overtime when exposed to light and heat

- The price is higher compared to polyamide (Exact price must be requested from Seido Solutions)

Can these be ordered yet?

Thank you for your enthusiasm and feedback!

This started as a kind of study project to get more insights in 3D printing technology.

But I do get a lot of positive reactions, so I’m doing some further testing and discussions with partners to find out whether it could works to bring the barrettes back on the market, in a way.

Regards K.